Industry 4.0

i+d

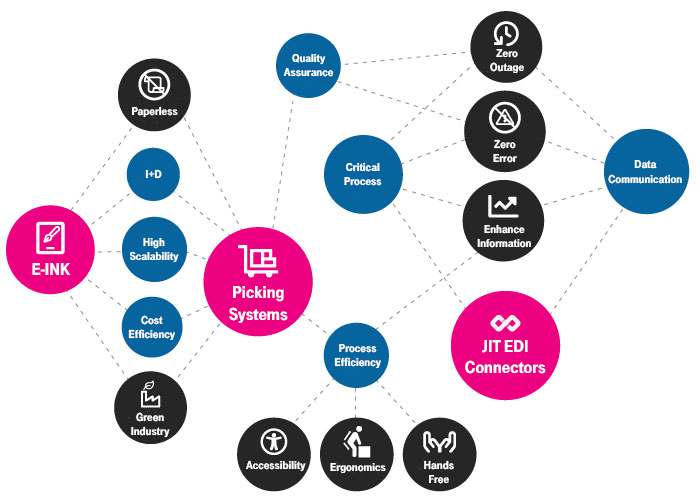

GIMM's modules are added value product extensions, ensuring information exchange with different OEMs (EDI) and optimizing logistics processes.

Synchron.Net

Synchron.Net is a web-based platform to create secure channels for the EDI communications between automotive suppliers and OEMS to make requests using both SOAP and REST protocols. Can work autonomously or integrated with LINCS. The obtained data can also be transformed to different file formats. Currently, the platform provides connectors to the web services of multiple OEMs:

- Corail, STELLANTIS / PSA certified connector for production data reception using Corail web services.

- SyncIP, PSA validated connector for production data reception using PSA SyncIP web services.

- PSFV+, Renault validated connector for the production data exchange.

- NGAVS/EBC system, Ford connector for the production data exchange using TCP/IP socket communication protocol.

- MOS, TESLA validated connector to all its factories, allowing connection to the TESLA MOS web service for production data exchange.

- LeanERP, SKODA Connector based on oDATA protocol for downloading DELFOR02 (call-off) files.

- Jaguar Land Rover Supplier Broadcast is the connector for the call-off and forecast production messages.

rvsEvo

Communications module using OFTP and OFTP2 protocols, used by Volkswagen and Daimler groups, to exchange JIT EDI data with their main suppliers. Can work autonomously or integrated with LINCS.

MCS

Configurable module to identify and monitor errors in OEMs EDI files content(for example, missing module, incorrect module or incorrect quantity).

Webpicking

Real-time web application to help production plant's operators and supervisors, in supplying materials to the assembly lines and warehouse processes.

- Multi-terminal and multi-device, can be run on several terminals simultaneously and on both mobile devices and conventional workstations (PCs).

- Integrable, can work autonomously or with an external MES system.

- Sustainable, reduces the need for paper use.

- Alert management, allows the operator to alert of any arising incident during the picking process tasks, reducing reaction time to any unforeseen event.

Pick/Put to Light

Picktolight management module of devices installed in each of the warehouse locations. These devices indicate the locations and quantities to be collected and / or replenished in each supply operation, optimizing the routes and reducing operations time.

Pick by Voice

Voice commands module to assist operators in warehouse operations, optimizing routes and reducing order operations process time. The operator can handle products hands free thus facilitating a comfortable and ergonomic work. This is a good option when visual systems cannot be used (for example in cold stores).

Pick by Vision

Module using Augmented Reality to efficiently guide operators during picking operations. Provides real time instructions and visual guidance to the operator. Focussed on picking processes in large spaces, where viewer indications (texts and signals) guide the operator. This module is currently in the prototype phase.

E-Pad

Electronic ink device designed to replace paper in logistics operations within warehouses and production lines. Consists of a set of various sizes labels that allows to display texts, images, bar codes and lists of data, as in a sheet of printed paper. This module is currently in prototype phase.